Trying to make your construction firm stand out? Tough gig. With tight margins, rising costs, and cutthroat competition, every project win matters. But here’s the kicker: it’s not the newest tech trend that’ll boost your profits. It’s smarter resource management.

Think about it. In construction, your real assets aren’t just materials or machinery; they are people, equipment, and time. Mismanage any of these, and deadlines slip, budgets balloon, and profitability tanks. Many firms still rely on spreadsheets or scattered tools that can’t offer a unified, real-time view of resource allocation.

It’s time to change that. Let’s unpack the role resource scheduling plays in the construction field and understand why implementing a resource management solution might be the hidden key to keeping projects running like clockwork and why mastering it could be your firm’s real competitive edge.

Construction projects are high-stakes chess games; one wrong move, and timelines, costs, or crew morale take the hit. Deadlines are tight, material costs fluctuate, weather is unpredictable, and skilled labour is always in flux. In this environment, smart resource management isn’t optional but crucial for survival.

Every construction site is a mini ecosystem of specialists:

Now, throw in temp labour, fluctuating demand, and equipment logistics, and you will feel chaos lurking at every corner. Poor resource visibility can cause:

And it’s not just manpower. Materials, machinery, and equipment inventory all compete for attention. Managing these moving parts with spreadsheets or siloed systems is like building skyscrapers with duct tape.

That’s where resource management steps in. It centralizes every moving piece, like people, plants, and planning, into one dynamic system. With it, project managers can forecast needs, schedule efficiently, and balance workloads before problems hit the site. The result? Projects that stay profitable, predictable, and on point.

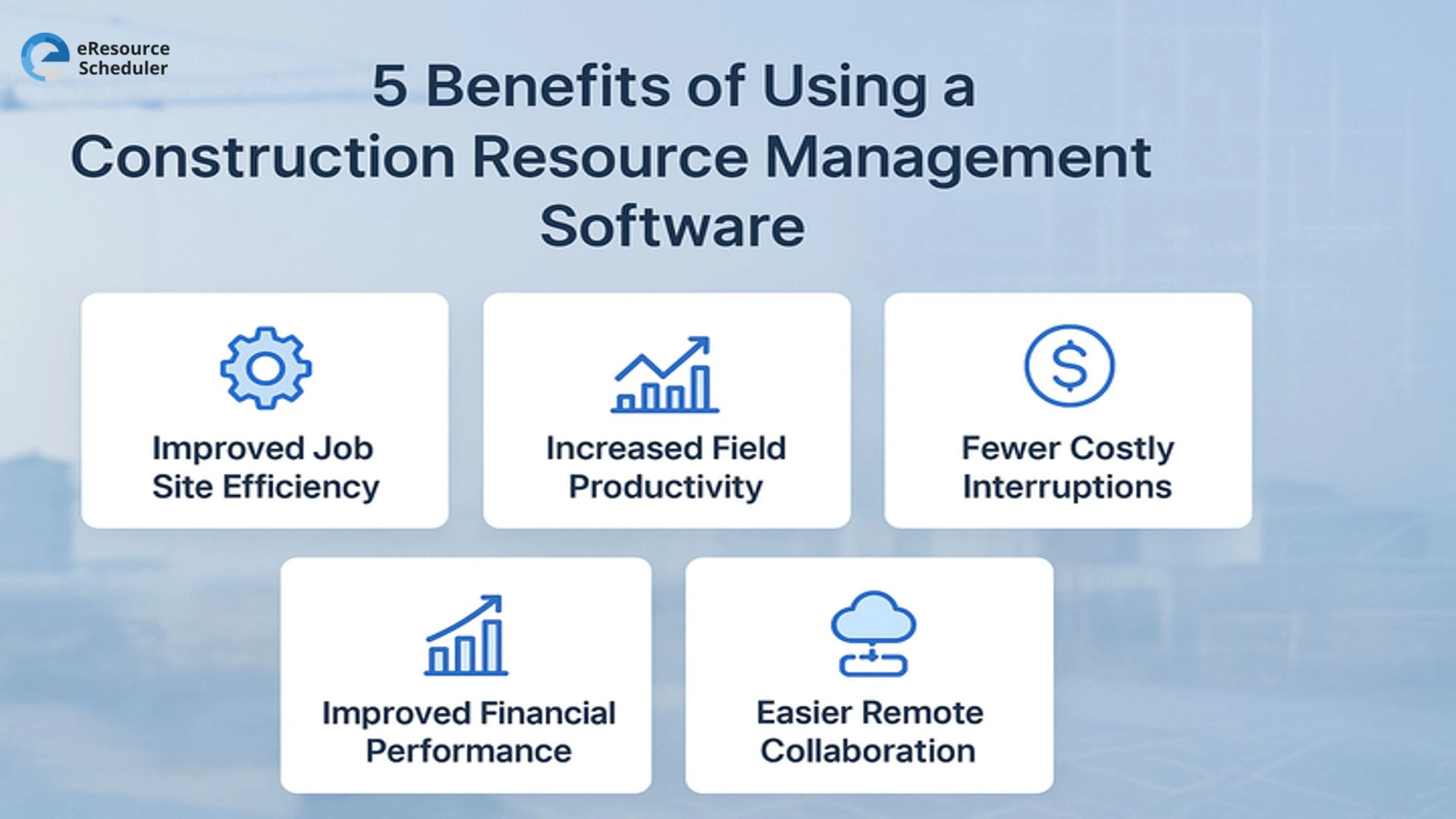

Resource management brings a host of advantages to construction project managers. Below are some key benefits that come from adopting the right construction resource management system:

A well-designed construction management system enables managers to monitor staff schedules, skill sets, and leave calendars, all while adjusting for demand fluctuations. It also supports resource forecasting, ensuring smoother on-site operations and preventing last-minute chaos.

Real-time visibility into resource availability means no more juggling spreadsheets. With eRS, managers get a centralized view of each worker’s skills, certifications, experience, and cost rate, thus making it easier to assign the right people to the right projects at the right time.

Compared to DIY systems like spreadsheets, a dedicated system minimizes human and planning errors. eRS automatically alerts managers about resource availability and capacity constraints.

The resource capacity planning capabilities of eResource Scheduler highlight potential gaps early, enabling data-backed decisions to manage shortages. For example, if a civil engineer takes unplanned leave, the system instantly shows available backups to keep the project on track.

With KPIs such as utilization, costs, and billable hours, managers can easily keep projects profitable. Tracking forecast vs. actual spending helps control costs and mitigate risks early. eRS also enables accurate estimates of labour, materials, and timelines, ensuring actual costs stay within projected limits.

Construction teams often manage multiple projects across different locations. Since tasks are interdependent, the estimator relies on the architect’s blueprint; for instance, clear communication is crucial.

eRS ensures everyone has real-time access to project timelines, budgets, and progress through a single dashboard. It removes guesswork, enhances visibility, and strengthens accountability across dispersed teams.

Implementing an effective process starts with visibility, like knowing exactly who, what, and where your resources are at any given time. Construction projects often juggle multiple job sites, shifting deadlines, and a mix of permanent staff and contract workers. Without a clear process, it’s easy for projects to fall behind or for resources to be underutilized.

List every available resource from skilled labour and subcontractors to equipment and materials. Include critical details like skills, certifications, availability, and cost rates. This inventory becomes the foundation for smarter allocation and forecasting.

Ditch the disconnected spreadsheets and introduce a unified scheduling framework. Centralized systems like eRS help you plan workloads, match skill sets to project needs, and forecast demand across multiple projects. The goal is to ensure that resources are always working at optimal capacity, not overbooked, not idle.

Construction is unpredictable. Materials get delayed, weather shifts schedules, and clients change scope midstream. Effective resource management means anticipating these shifts. Use forecasting tools to model scenarios and adjust resource plans dynamically before issues escalate.

An effective process thrives on collaboration. From architects to engineers, everyone should have visibility into project timelines, changes, and dependencies. A shared dashboard ensures that the right people get updates in real-time, minimizing rework and delays.

Once your process is live, continuously monitor performance metrics like utilization rates, idle time, and cost efficiency. Review outcomes post-project to identify bottlenecks and areas for optimization.

A structured, data-driven resource management process helps construction firms stay nimble, efficient, and profitable no matter how complex the build.

In construction, efficiency isn’t just about finishing on time but also about staying profitable, predictable, and prepared for what’s next. Smarter resource management gives you that control. It aligns people, equipment, and schedules into one streamlined system that reduces chaos and amplifies output.

By replacing spreadsheets with real-time visibility and data-driven decisions, construction companies can minimize waste, maximize utilization, and stay agile amid shifting demands. It’s not about working harder, it’s about planning smarter.

As projects get larger and timelines tighter, the firms that thrive will be those that treat resource management as strategy, not administration. With the right process and technology, every project becomes less of a firefight and more of a blueprint for long-term success.

1. What is construction resource management?

Construction resource management is the process of efficiently planning, allocating, and tracking people, equipment, and materials across projects to ensure timely, cost-effective delivery.

2. Why is resource management important in construction projects?

Because even one mismanaged resource—be it labour, machinery, or time—can derail an entire project. Smart resource management helps control costs, prevent delays, and boost productivity across job sites.

3. How does construction resource management software help?

It centralizes data on people, equipment, and schedules, giving project managers real-time visibility and forecasting tools. This helps prevent overbooking, idle time, and last-minute chaos.

4. What are the key benefits of using a tool like eResource Scheduler?

eRS enhances job site efficiency, boosts field productivity, reduces scheduling errors, improves financial control, and enables seamless collaboration across remote teams.

5. How can a construction firm start implementing smarter resource management?

Begin with a complete resource inventory, adopt centralized scheduling software, use forecasting for scenario planning, maintain transparent communication, and continuously track utilization metrics to improve efficiency.

Plan Smarter. Schedule Faster.

Join thousands already using eResource Scheduler to align teams, time, and tasks seamlessly.